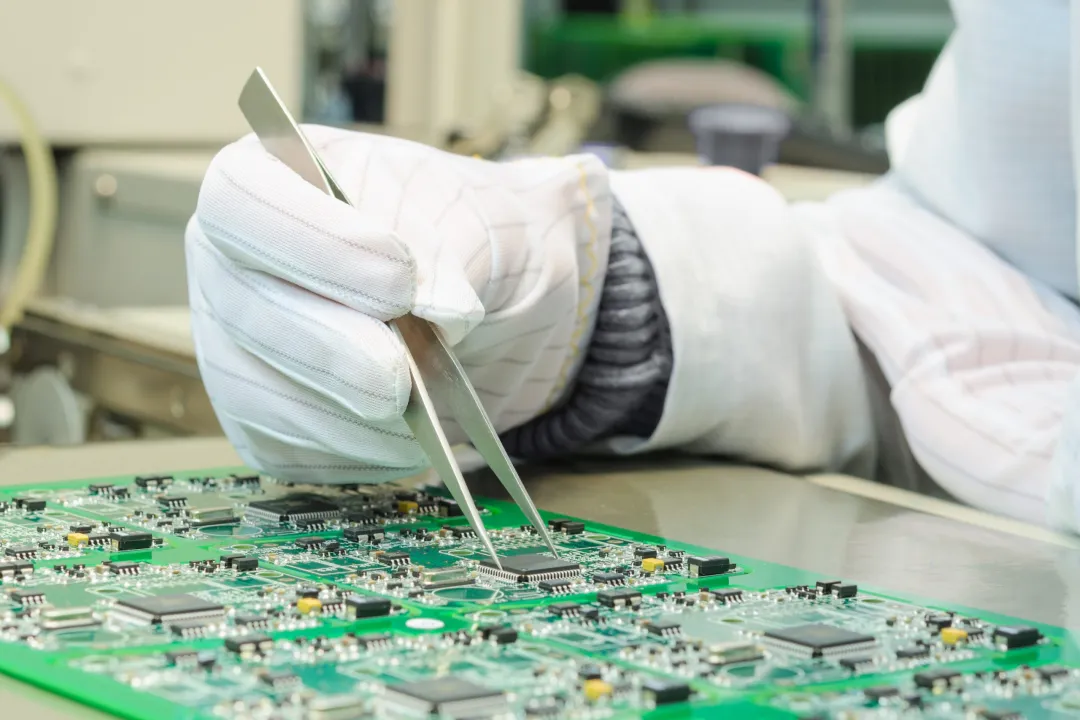

At present,Asind has been manufacturing PCB for many industries,like medical and health care,automotive electronics,smart home, industial

control,artificialinteligence,and the interet Things,ect.

we also have obtained 1S09001,1$013485,1S014001, ATF 16949,UL and othauthoritative cerifcations at home and abroad,