MES, short for Manufacturing Execution System, is a shop-floor-focused management information system that sits between the upper-level enterprise resource planning (ERP) system and the lower-level process control system (PCS/PLC). It acts as a critical "bridge" connecting production planning and on-site execution.

The core of MES lies in real-time data collection and closed-loop management, which enables full transparency, traceability and controllability of the entire production process.

Its key functions include work order scheduling, production execution management, quality control, equipment monitoring, material traceability, data acquisition and visual dashboard display.

By breaking down ERP-level production plans into detailed process-level instructions and feeding back real-time production status (such as progress, bottlenecks and quality issues), MES forms a closed loop of "planning → execution → monitoring → optimization" to improve production efficiency, reduce costs and enhance product quality.

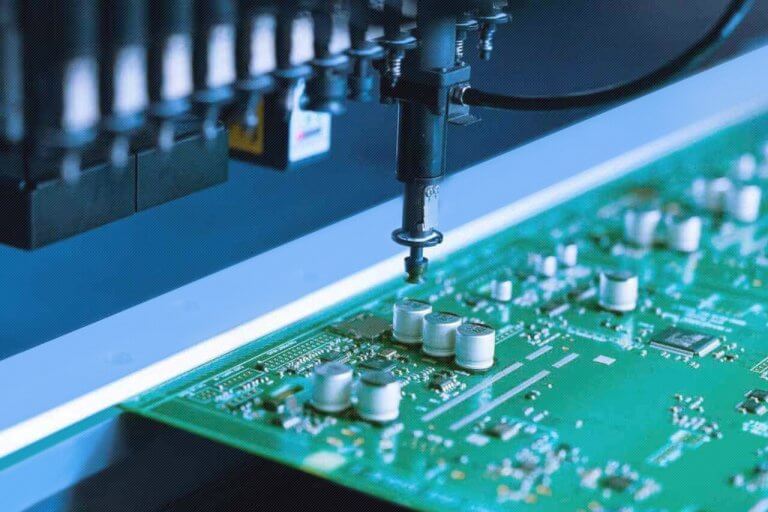

In the Asinda workshop, we have implemented a full-process MES system management, achieving visual and traceable management of each production stage, significantly enhancing the efficiency of product quality control, and truly achieving zero defects in PCBA production.