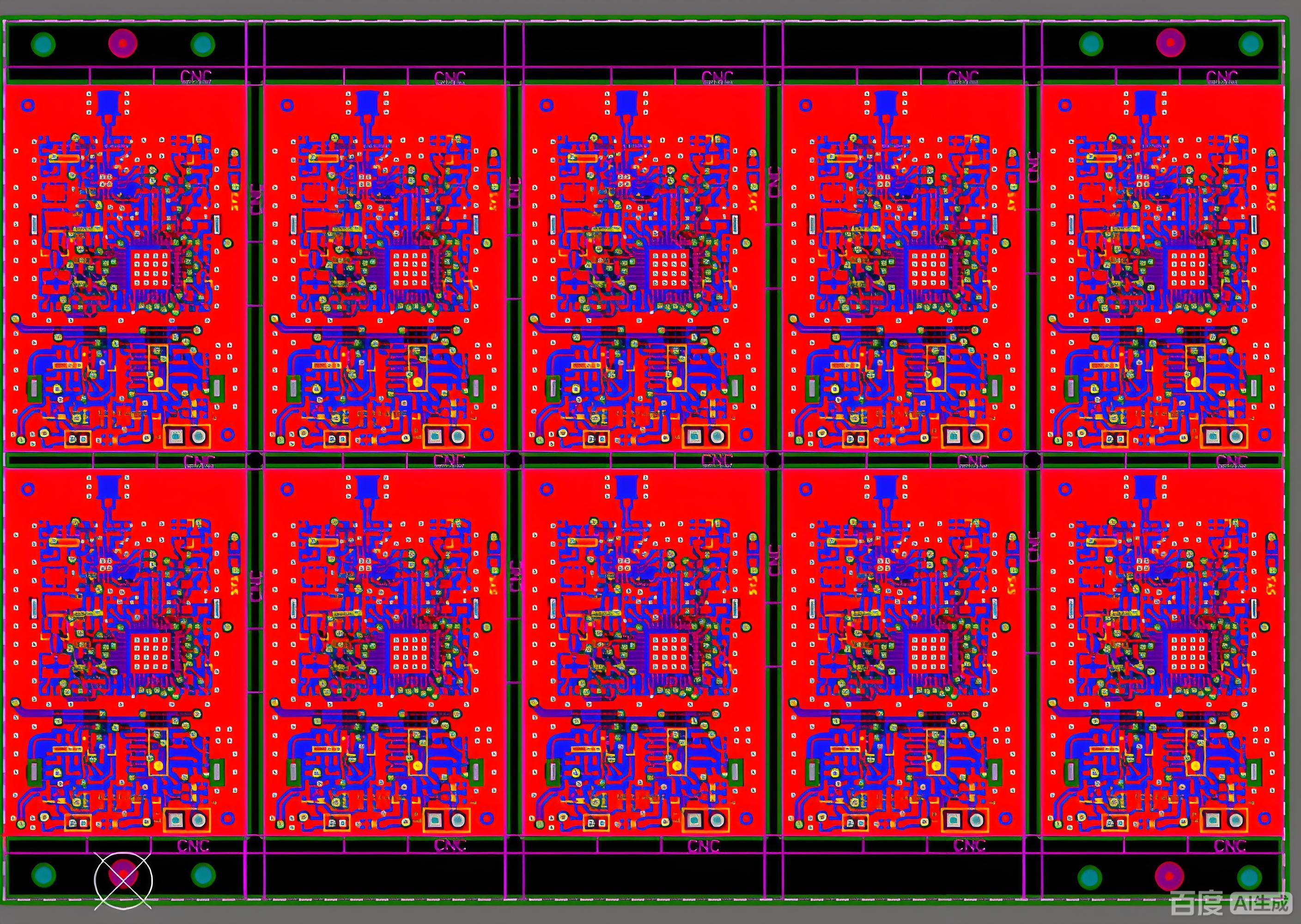

The quality of PCBA directly determines the performance and reliability of the product. X-ray inspection technology can ensure the quality of your products.

X-ray inspection: Detecting invisible defects

X-ray inspection is an indispensable part of the PCBA manufacturing process, especially when it comes to checking the soldering quality of hidden solder joints such as BGA (Ball Grid Array) and QFN (Square Flat Leadless Package), it plays an irreplaceable role. Advanced X-ray inspection equipment can:

● Penetrate the PCB and clearly display the soldering condition of the internal solder joints;

● Detect defects such as voids, cold welds, and short circuits at solder joints to ensure the reliability of each solder joint;

It provides high-precision image analysis to help engineers quickly locate problems and optimize production processes.

Asinda is equipped with multiple high-precision X-ray inspection devices, including:

● Automatic X-ray Inspection Instrument (AXI) : Supports batch inspection, with an efficiency as high as 99.9%;

●3D X-ray imaging technology: It can conduct stereoscopic analysis of the welding quality of complex packages.

● Intelligent defect analysis software: Automatically identify and classify defect types, and generate detailed reports.

We inspect each piece of PCBA one by one through X-rays, which enables:

1. Enhance product reliability

When electronic products operate in extreme environments such as high temperatures and vibrations, soldering defects may lead to functional failure. X-ray inspection can detect potential problems in advance and avoid batch failures.

2. Reduce rework costs

Traditional manual visual inspection is difficult to detect hidden defects, while X-ray inspection can monitor in real time during the production process, reducing the costs of rework and scrapping in the later stage.

3. Meet industry standards

High-demand industries such as medical care, automobiles, and industrial control have strict standards for PCBA quality. X-ray inspection is a key means to ensure compliance.

X -ray insprction is one of the most important process in PCBA quality control ,Our engineering team combines X-ray inspection data to optimize the production process and ensure that each PCBA meets the high standards of our customers.