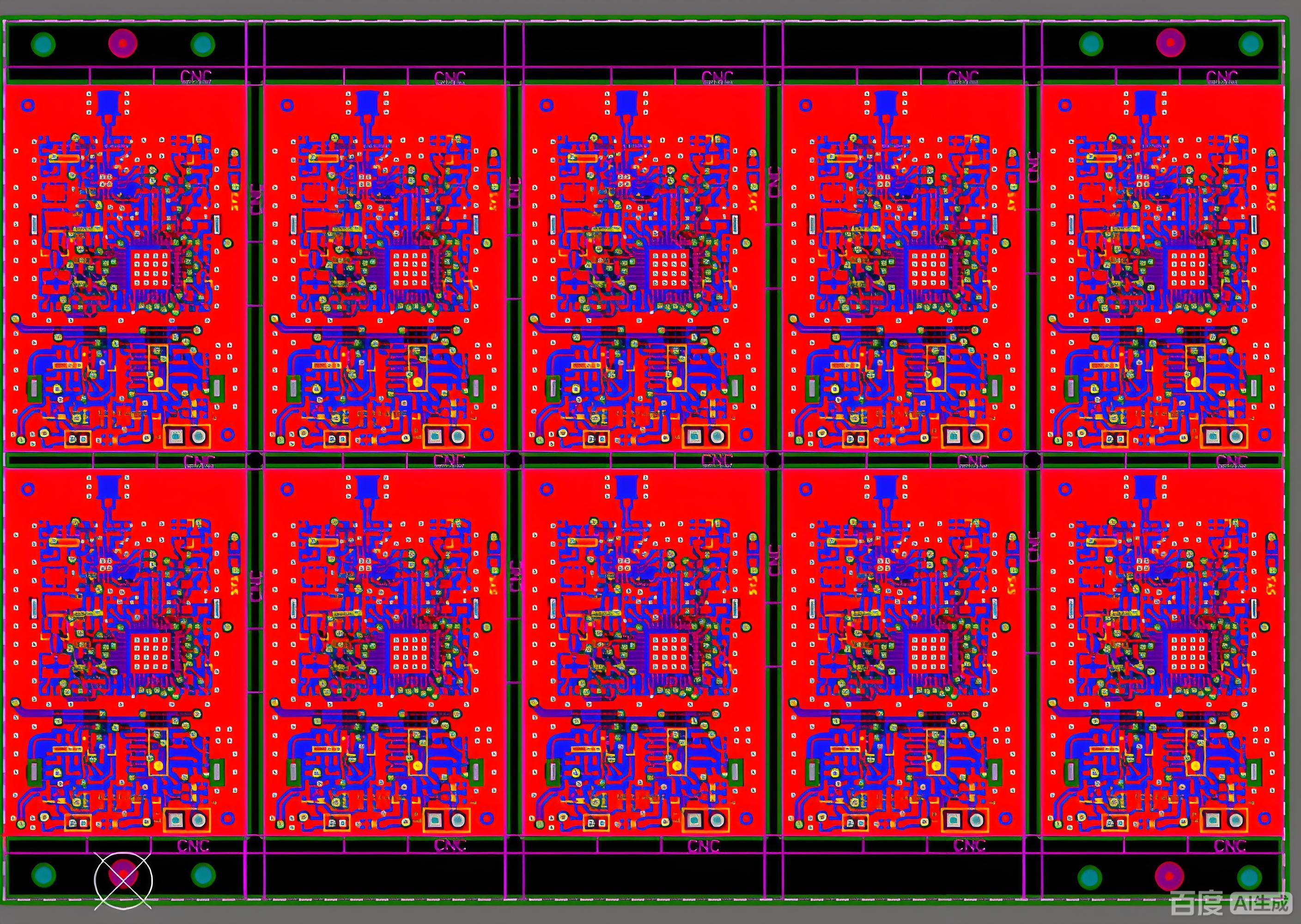

What are V-cuts and stamp holes?

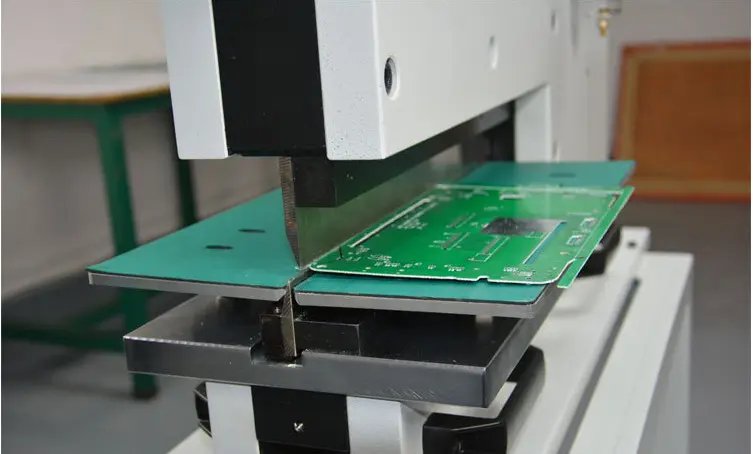

V-cut refers to the V-shaped dividing line between two boards and between the board and the process edge, forming a "V" shape; Break apart after welding.

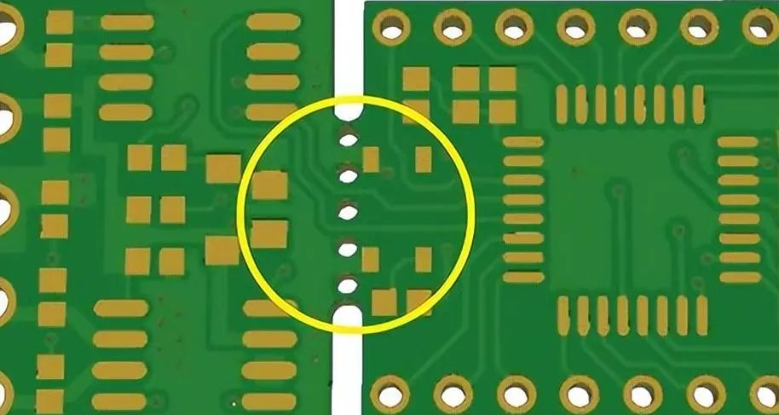

Stamp hole is the motherboard plate inside, the small board and the small board need to be connected between the tendon, in order to facilitate cutting, the tendon will be opened up some holes, similar to the stamp edge of the kind of hole.

Stamp hole and V-CUT ,which is better for PCB panle?

In fact, each has its own advantages, each has its own disadvantages.

When using a double-sided V-shaped groove, the depth of the V-shaped groove should be controlled at about 1/3 (the sum of the two sides of the groove), requiring accurate groove size and uniform depth.

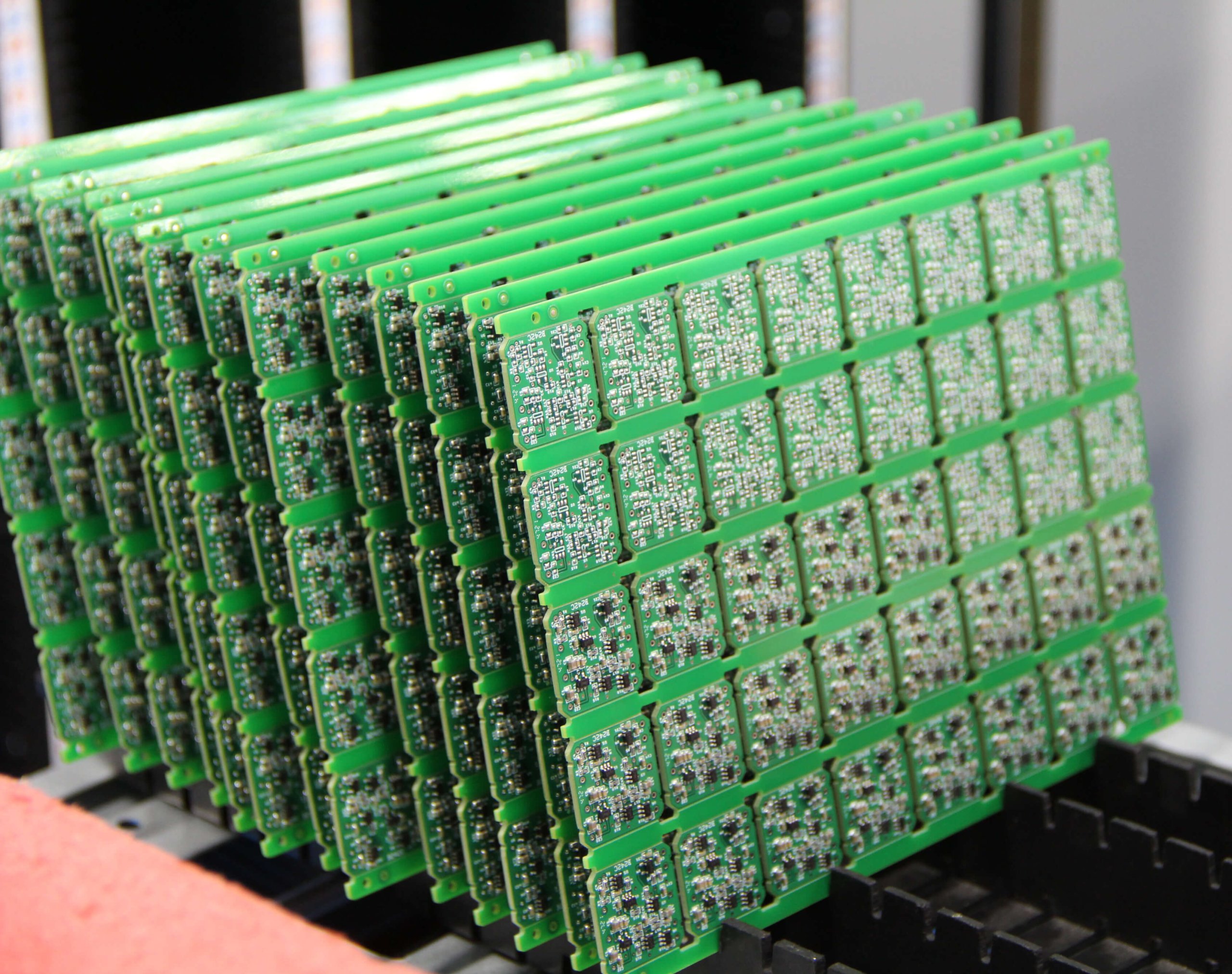

When using the stamp hole, it should be noted that the edge should be evenly distributed around each piece of the board to avoid deformation due to uneven stress on the PCB during welding.

The position of the stamp hole should be close to the inside of the PCB to prevent the residual burr at the stamp hole after the separation of the board from affecting the customer's complete machine assembly.

For irregular PCB such as circles, V-CUT can not be done, so it is necessary to use stamp holes to make panel connections, so stamp holes are used more in shaped plates.