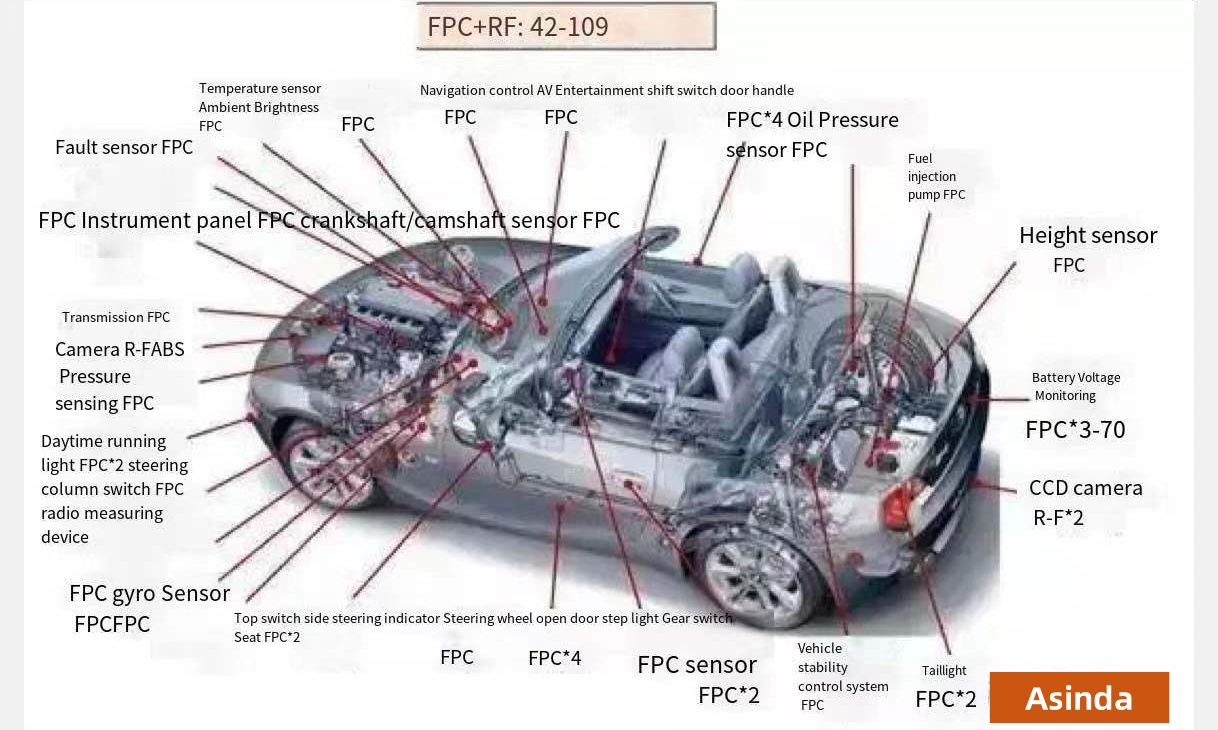

In an electric vehicle, as many as 100 FPCS may be used. Among them, FPC applications in battery BMS and vehicle camera modules have the highest value and are also the focus areas of current development.

Especially in the battery BMS, because the cost and space utilization of the battery are key issues, the technical development of the current battery capacity is close to the limit, so it is necessary to seek efficiency improvement from the structural design. Using FPC instead of the traditional BMS wiring method not only ensures performance stability, but also reduces the risk of upper cover friction caused by breathing. In the long term, the circuit of the motherboard and slave board may even be replaced by chips, and these chips can be installed on the FPC, thereby improving the stability of the product, saving space and reducing costs (although the cost advantage is not yet visible). The process of technology iteration often involves a more fundamental level of improvement.

In new energy vehicles, the FPC collection line application in the battery BMS system is crucial to monitor the voltage and temperature of the power battery cell, achieve data collection and transmission, and have overcurrent protection function to protect the cell from abnormal short circuit.

In the past, the new energy vehicle power battery collection line usually adopts the traditional copper wire harness scheme, but when a large number of current signals need to be processed, this scheme will take up a lot of space. In contrast, FPC has significant advantages in terms of safety, lightweight, and regular layout due to its high integration, ultra-thin thickness, and ultra-flexibility.

The thin thickness of FPC makes the battery pack structure can be customized, and the assembly can be grabbed by the mechanical arm and placed directly on the battery pack, which has a high degree of automation and is suitable for large-scale production, so the trend of FPC replacing copper wire harnesses is obvious.

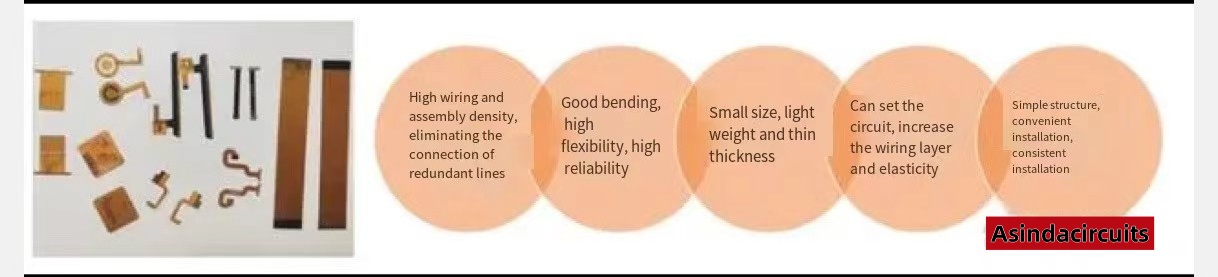

In the power battery module, FPC has the following advantages:

Highly integrated: Fuse, connector, chip NTC and aluminum/nickel terminals are integrated to provide excellent and consistent electrical performance, adapt to the needs of miniaturization and high-density installation, realize three-dimensional space wiring and flexible shape changes, and meet the requirements of integrated component assembly and wire connection.

Automated assembly: The assembly speed is fast and accurate, which is conducive to automation. FPC sampling can reduce the complexity of Module integration process, and the connection between FPC and battery busbar can realize automatic welding, effectively reducing labor costs. Even in the case that automatic welding cannot be achieved, the traditional screw locking method can still reduce manual input.

Ultra-thin thickness: the thickness of the line area is only 0.34mm, and the NTC is 2mm.

Ultra-soft: the line area can be bent and assembled at 90° and 180°.

Lightweight: When used in the whole vehicle, the weight can be reduced by about 1kg compared to the wire harness scheme.

Cost advantage: Although the cost of FPC itself is not high, its connection cost is greatly reduced compared to traditional solutions.

Due to the advantages of high integration, ultra-thin thickness and ultra-softness, FPC is superior to copper wire harness in terms of safety, lightweight and regular layout. In addition, the FPC's thin thickness and customization capabilities enable automated assembly via robotic arms, making it suitable for mass production.

Therefore, the trend of FPC replacing copper wire harnesses is clear. At present, the FPC solution has become the first choice for most new energy vehicles. The FPC is being integrated into Cells Contact System (CCS). It combines with plastic structural components and copper and aluminum bars to form structural components for electrical connection and signal detection.